Voices in the Coalshed: Mining Words

Creep, slice, strip or steer – what can these words tell us about mining?

A long wall coal face of 250 metres in length will be accessed at either end by two tunnels or roadways, which are called “Gates”.

When a coal face is developed prior to production, the coal face will be set out at 90 degrees or right angles to the gates. The Armoured Flexible Conveyor (AFC), that extends along the face will be positioned to allow the coal face to advance whilst allowing the gates to follow in a straight line.

Keeping the gates running in a straight line is extremely important, especially for the gate that carries the mineral out of the mine. This gate will be served by a standard conveyor belt and conveyors really love to run in straight lines, they do not tolerate going around corners.

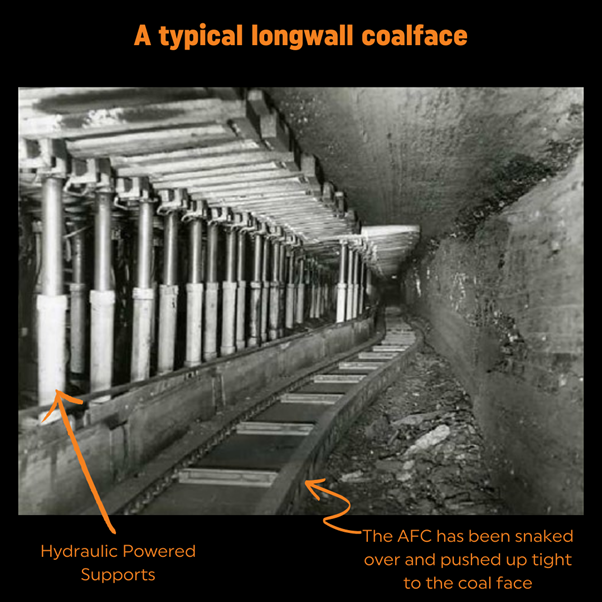

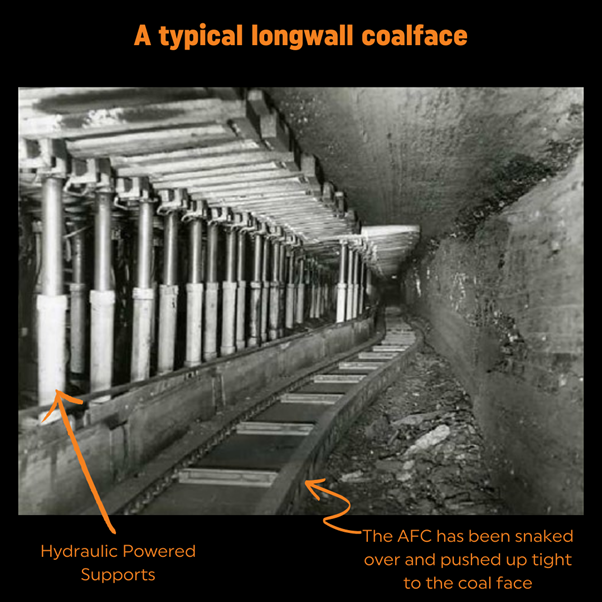

This picture shows a typical long wall coal face. In the background the AFC has been snaked over and pushed up tight to the coal face, the hydraulic powered supports have also been advanced behind the AFC.

The coal face is being prepared for the ‘BACON SLICER’ machine otherwise known as the “SHEARER” to make its way along the coal face following the AFC whilst slicing off another section of coal otherwise known as a “STRIP”

Once production has begun on a newly developed coal face, the AFC will have a tendency to begin to move from its original setting out position. The full length of the AFC will begin to “CREEP” in one direction or another down the length of the face.

The result of this creep means a lot more hard work may have to be carried out in the gates in order to keep them running in a straight line. Therefore it is imperative to stop the AFC creeping in a certain direction and to bring it back on line, by reversing the creep.

One way to control face creep was to ”STEER” the coal face. This meant pushing the face in a different direction. The shearer driver would concentrate on cutting thicker sections of coal at one end of the face as opposed to the other. The face would then not be at 90 degrees or right angles to the gates and so the face would start travelling in a slightly different direction and as such the AFC would then begin to return to where it should be.

Once the AFC did begin to move in the right direction the face could be once again squared up with the gates.

Can you share any special terms used in your job?

Voices in the Coalshed is a volunteer-led project that explores the language and literature inspired by coal mining.