Explore the Museum

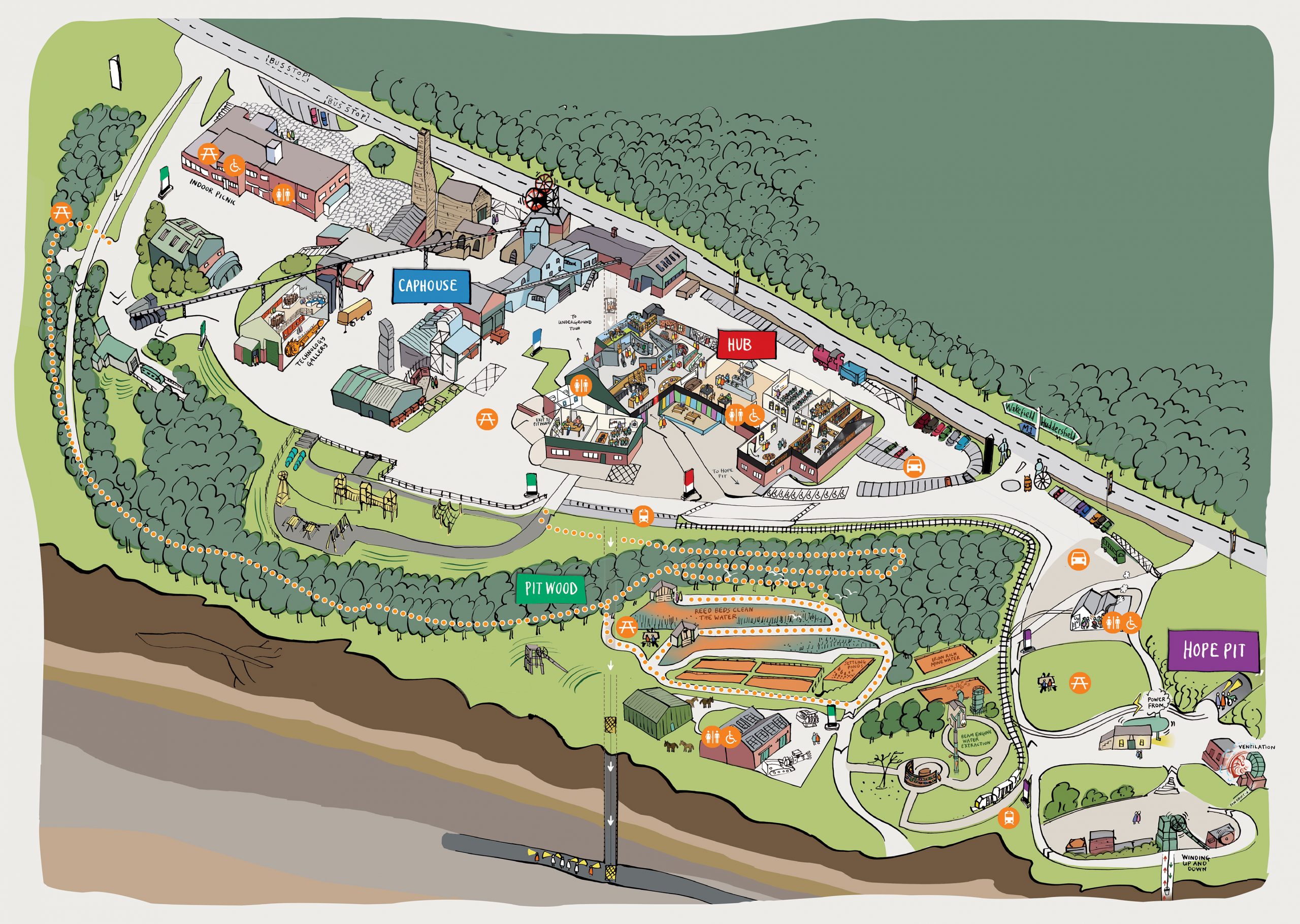

Welcome to our Interactive Map. Here you can dig deeper into each area of the Museum: discover the history of our colliery buildings; see and hear from the people who worked underground; download fun activities that you can enjoy from home; and much more! Click on the zones below to begin your virtual journey.

"*" indicates required fields

-

Caphouse

-

Welcome to Caphouse

Experience the Life of a Working Colliery.

This site was a modern colliery until it closed after more than two hundred years of coal production. See what a 1980s pit was like and meet the people who worked in the industry.

-

Caphouse Pit Yard

The Pit Yard was the heart of the colliery.

The Pit Yard has always been a hive of activity with coal wagons or coal lorries constantly in and out to load up with coal. Defined by the strange collection of temporary buildings that grew up around the headstocks. Yards were also storage spots for spare cages, wooden pit props and other spare parts.

-

Weighbridge

Meet Alan and find out how coal was transported when it left the pit.

The Weighbridge is a massive set of scales used for weighing lorries and the coal they carried. Meet Alan, the weighbridge man at Caphouse when the colliery closed. It was his responsibility to weigh all the coal that left the site and who had bought it.

-

Underground Tour

Journey 140 metres underground and experience what it was like to work in a mine.

Get kitted out with your hard hat and battery lamp then step into the ‘cage’ to descend 140m underground to discover the harsh realities of coal mining through the centuries. Hear all about your guide’s working life and experiences in the coalmine.

Discover the different ages of mining, from Victorian times when women and children worked underground alongside men, find out about the role of pit ponies and how modern machinery changed coal mining.

-

Furnace Shaft

Look down the 140m furnace shaft and see how deep our mine goes.

The shaft once helped to provide the fresh air needed to work safely underground. After surviving about 130 years, an HLF grant enabled the Museum to complete much needed repairs and now allow visitors to look down into the glass-capped shaft.

-

Screens Building

The Screens Building, where coal was cleaned and sorted, is accessible through guided tours on specific days.

The Coal Screening Plant or Screens Building was used to clean and sort the coal when it had been hauled to the surface. The building or more accurately, this collection of structures were built over time, made of tin sheeting and wooden floors and evolved as the pit grew.

Currently the Screens are not open to the public but on certain days, the Museum runs special Screens tours. For more information about Screens tours, ask at the Welcome Area in the Hub.

-

Steam Winding House

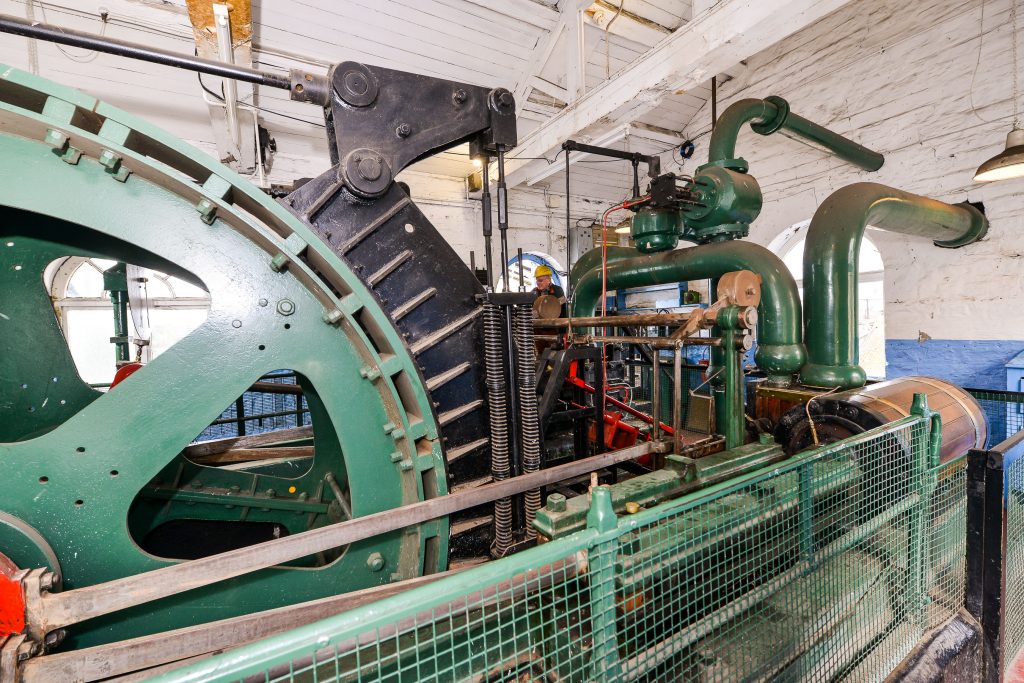

See our steam-winding engine which, for over 100 years, moved men and coal in and out of the pit.

Winding is about getting the miner into the pit and the coal out. As mining went deeper, winding machines improved. A winding engine is a large winch which hauled cages up and down the vertical mineshaft.

-

Victorian Gallery

Find out how 1842 changed the lives of women and children forever.

The Victorian Gallery examines what mining was like in the 19th century. In 1842 the first coal mining act of Parliament banned women, girls and boys under 10 from working underground. Discover the conditions in mining at that point and the effect of the first legislation to touch the mining industry.

-

Lancashire Boilers

For over 100 years, Lancashire Boilers created the steam that powered the colliery’s winding engine.

It was steam that powered the Industrial Revolution. The steam engine used pressure, produced by steam, to move a piston back and forth. The force of the piston was transformed, by a connecting rod and flywheel, into a rotational force which powered machinery. Steam provided reliable power and could be used to run large machines, like steam winders and colliery fans.

At present, the Boiler House is closed to the public. Members of our volunteer conservation team are currently working on a project to restore them.

-

Pithead Baths

Experience where miners started and ended their working day.

Visit the place where miners started and ended their day. Pithead baths started to be built in the early 20th century. Before then, miners would have to travel home every day, covered in coal dust.

The baths were overseen by the baths attendant whose job it was to clean, keep things tidy and sell things like soap, towels or even chewing tobacco.

At the far end of the baths, have a peek inside the medical centre. This is where the pit nurse would be based unless she had to go underground to deal with a casualty.

-

Control Room

Understand how computers on the surface monitor conditions and production underground.

Colliery-control rooms are used to monitored and troubleshoot operations underground and have come to play a vital part in the smooth running of a pit.

-

Technology Gallery

Discover how miners overcame the challenges of working underground.

Find out about the men and machines that worked underground and see what equipment helped the industry develop. So come and take a look at some of the tools of the trade!

Downstairs you can see how miners overcame the many challenges of working underground. How they conquered the darkness underground. And how they developed machines to cut the coal. Upstairs you can see how coal was transported. See how people communicated underground from signal wires to our modern mining control room from Kellingley colliery.

-

Kellingley Memorial

The Kellingley Memorial commemorates miners who died at Kellingley Colliery since its opening in 1958.

The Memorial originally stood outside the pit offices at Kellingley Colliery, West Yorkshire, the last British deep mine. The memorial commemorates miners who died at Kellingley Colliery since its opening in 1958.

When it was decided to close Kellingley in 2015, the memorial was carefully taken down and reassembled near the Screens Building at Caphouse. It now stands not just for those that died at Kellingley but marks the end of the last British colliery.

-

Welcome to Caphouse

-

Hope Pit

-

Welcome to Hope Pit

Discover the Mechanics of Mining.

Explore the buildings around Hope Pit and see how science and engineering were used on the surface to support the vital work done underground.

-

Hope Pit Yard

Discover the Mechanics of Mining.

The small scale of Hope Pit’s remaining buildings was typical of many small, rural, 19th century collieries, yet over the years, Hope Pit developed to support Caphouse and their histories are bound together. Through these buildings we can see some of the vital processes needed to support the miners underground.

-

Blacksmiths Workshop

Visit our repair shop and see a real working forge.

Keeping machinery running and the tools mended was a full-time job. The blacksmith’s and fitting shop were hives of activity as coal cutters, conveyors and other vital pieces of equipment were overhauled and repaired.

-

Tunnel

If you can’t go underground, why not try our overground underground experience.

At present, our overground underground gallery is only open to guided tours. The Hope Pit Explore tours are pre-booked tours and are only available on specific days.

For more information, ask about the Hope Pit Explore at the Welcome Area in the Hub or consult the events pages of the website, here.

-

Compressor House

Discover the power of air and how it was harnessed to run machinery underground.

Pneumatic power uses the energy in compressed air to transmit force. Air that has been compressed contains energy and, when released, the resulting airflow can be used to power machinery such as motors, turbines or pistons.

-

Fan House

Come in and find out why clean air and good ventilation saved so many lives.

Visit the Fan House to find out about the importance of ventilation, ensuring miners had fresh air to breath throughout the mines. See some of the smaller fans used to ensure good air was driven through the roadways. See what equipment deputies used to check ventilation speeds and quality of air.

-

Electric Winding House

Meet Mr Roberts, and learn about one of the most important jobs at the pits.

Come up and visit our Electric Winding House and meet Mr Roberts. Mr Roberts was a winding engineman and will tell you all about the art of winding. See our working electric winder which was still in use when the pit closed in 1986.

-

Inman Pumping House

Find out how miners overcame the problems of water underground.

The Inman Pumping House is the oldest building on site and has pumped water out of the mine since the 1840s. Water created a major problem for the mining industry. Come inside and learn about the dangers of water underground, the importance of pumping water out and where it goes afterward.

-

Miners’ Memorial Garden

Contemplate and reflect on the lives of miners and their communities.

A place for quiet contemplation and reflection, the Miners’ Memorial Garden celebrates and commemorates the courage and camaraderie of our miners, and the close-knit families and communities that supported them.

The centre piece of the garden is a specially commissioned art installation, ‘Lives Lived, Lives Lost’. This was the concept of renowned public artist Stephen Broadbent and represents the spirit of mining. The design is curved in shape to link with aspects of the industry such as cutting machines and pit wheels. The voids in the Corten steel screen represent the tunnels, strata and confined spaces underground.

-

Power House

Come and see the mighty machinery that was used across our industry.

The Power House is where you can find some of the large machinery in the Museum’s collection. Delivery lorries and coal-loading machines to underground locomotives and coal-cutting machines, there is a great deal to see of the unique machinery used in the mining industry.

The Power House is also where much of the Museum’s conservation takes place. See how and why we conserve our objects, what problems can affect museum objects and what conservator can do about them.

At present this store is open on weekdays during holidays.

-

Welcome to Hope Pit

-

Hub

-

Welcome to The Hub

Welcome to the Site and the Story of Coal Mining.

It’s here that you can find everything you need to plan your day. See what’s on, book an underground tour and explore our exhibitions to learn about the life of a coal miner.

-

Welcome Area

Find everything you need to make the most of your day.

Here, in the middle of everything, is where you can find all you need to enjoy your day. This is where you can plan your day, book an underground tour, browse our shop and learn a little of what went on in the life of a coal miner.

-

Mining Lives

Find out about the people and communities at the heart of the industry.

The Mining Lives exhibition tells some of the stories of mining. From rescue and welfare to hobbies and homelife, the galleries reveal the human element in mining and the communities that built up around the pits.

-

Special Exhibitions Gallery

Visit our Special Exhibition Gallery to see the latest exciting exhibition.

Our special-exhibition programme runs throughout the year on all sorts of subjects related to coal mining. Past exhibitions have looked at union banners, pit ponies and the Nationalisation of the industry.

-

Learning Space

Visit our activity area for all types of hands-on workshops and arts and craft activities.

The Learning Space is our flexible area where school activities and holiday workshops take place. It is also where we hold our Wacky Wednesday’s events.

-

Community Space

Be inspired by the work of people from coal-mining communities.

The Community Space is a gallery which gives the Museum the opportunity to show the work of community groups and artists. Members of the public can use it to showcase their artworks and projects.

-

Library

A mine of information on the history of coal-mining.

The Library holds a wealth of information on the history of coal mining in England – not only the geographical and technical sides of mining coal, but also the social, economic and political aspects of the industry and the communities it touched.

The collection holds current mining journals and journals from the nineteenth century as well as rare books dating from the 1700s, these include De Re Metallica which is not only the Library’s oldest book but also the oldest man-made artefact at the Museum.

-

Conference Centre

Caphouse Colliery offers a unique venue for conferences, exhibitions and private events.

The Conference Suites at National Coal Mining Museum are interchangeable spaces designed to offer maximum flexibility. Offering flexible spaces, ample car parking and a truly dedicated team, The team ensures that your meeting, event or conference is nothing short of first class.

-

Welcome to The Hub

-

Pit Wood

-

Welcome to Pit Wood

Explore the Changing Landscape of Mining.

Why not enjoy the scenic route and take some time to explore our peaceful woodland. See how nature has reclaimed the old colliery spoil heap and why we need to treat the orange mine water. Don’t forget to visit the Pony Discovery Centre and the Adventure Playground too!

-

Water Treatment Plant

See how we transform orange mine water into clean river water.

We need to pump over 4 million gallons of mine water per week to ensure the safety and dryness of the underground. It doesn’t come out clean and it’s the Museum’s responsibility to treat the water before it goes back into streams and rivers. As it moves through the rock and strata it picks up minerals, including iron pyrite. This is what gives it a rusty colour.

Natural chemicals in mine water will “settle out” if the water is still for long enough. The lagoons are settling tanks used to separate the orange ochre from the water pumped from the mine. The orange colour comes from the amount of ironstone in the strata around Caphouse. The water filters through the settling tanks, leaving more and more ochre behind before finally feeding into reed beds which become a natural sieve for the water.

-

Pony Discovery Centre

Meet our pit ponies and find out how they helped miner move coal.

Pit Ponies were an important part of the workforce during the 19th and 20th century. Visit the Centre to see some of the types of ponies used underground and learn about the jobs these workhorses had to do every day.

-

Nature Trail

Explore the woodland, spotting plants and wildlife along the way.

A stroll along the Nature Trail is a great way to enjoy the fresh air and our countryside setting. Along the way you can enjoy the tranquillity of nature among the birch, oak and ash woodland, find out about the plants, trees and wildlife that make their home here and see what you can spot from the bird hides.

-

Bird Hides

Enjoy the sights and sounds of nature from our bird hides.

Interested in spotting some wildlife? Why not try out our bird hides and see what you can spy. Nestled in our reed beds which attract all kinds of fauna, it’s an ideal space to relax and immerse yourself in nature.

-

Adventure Playground

Imagine, play and make your own adventures.

Let the kids run off some steam during your day in our mining-themed adventure playground with a range of exciting equipment for them to play on.

If you are coming onsite to use the playground, please check in at the Welcome Area, it helps us know how many visitors are onsite.

-

Drift Mouth

See where the coal leaves the mine on its way to the screens.

This mysterious gate leads to the Caphouse Drift. A drift is a sloped roadway leading out of the pit. It allowed coal to be transported from underground to the surface by conveyor belts. Drifts are also the emergency exit for the workers and an entrance for mine rescuers.

-

Welcome to Pit Wood